At Red Steel, it’s all about creating efficiencies to ensure deadlines and budgets are met.

Since 2002 Red Steel managing director Bob Hawley and his team have honed their processes and focussed on increasing production from their Pandora workshop.

Red Steel has developed streamlined processes within its supply chain, introduced smart software to track all projects, and invested in equipment that enables a turnkey project solution.

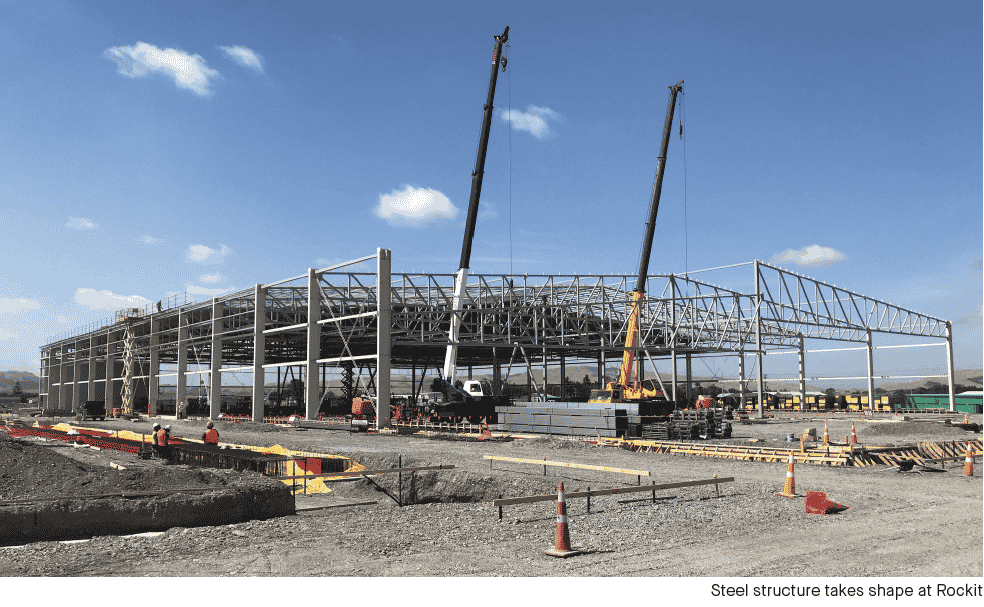

Red Steel started work on the project in August 2019 in the very early stages of the construction of the 20,600m2 post-harvest facility for Rockit Global.

The state of the art facility in Irongate was predominantly built of steel. In fact the building is made up of 33, 346 pieces of steel, which span a total of 57 kilometre and weighing 1012 tonne!

Red Steel managing director Bob Hawley says it’s been one of their major projects over the last year with the majority of the 39 strong workforce of detailers, fabricators and site crew involved in the project.

The steel was transported to the site and put together using 23,425 bolts. Working to a tight construction programme we staged our on-site activities to allow follow-on trades to commence work as we progressed down the building.

Bob says the Rockit project is the second largest food processing facility they’ve been involved with and he’s particularly proud that it was all done in house.

First published by The Profit. Click here to read the full article.